https://www.usa.gov/copyrighted-government-workshttps://www.rawpixel.com/image/12306831

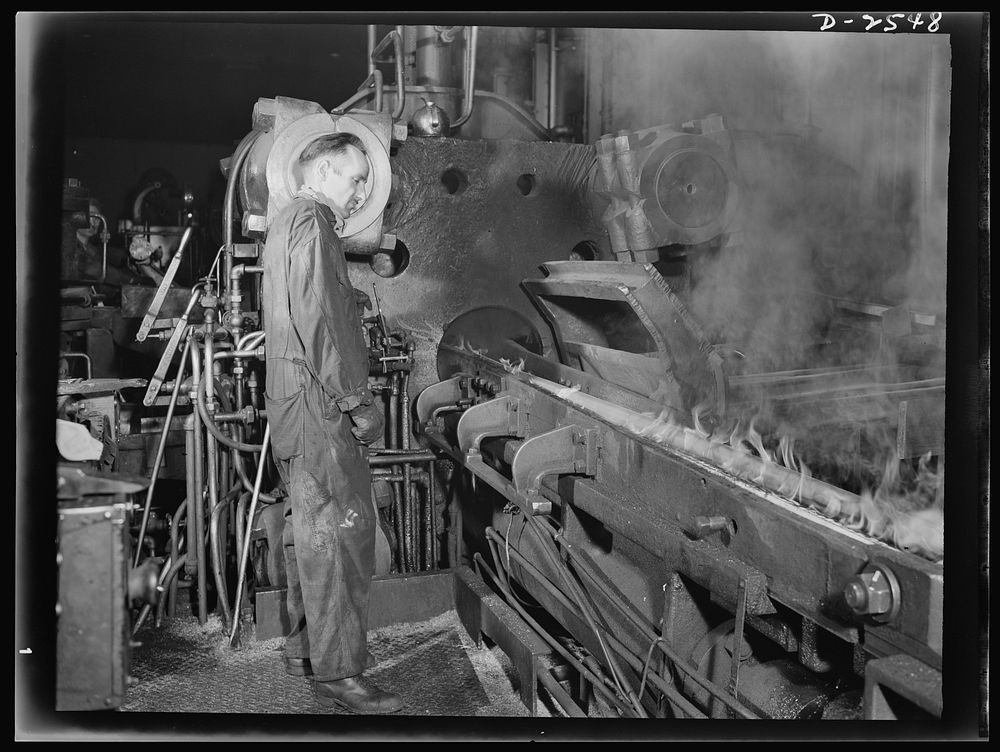

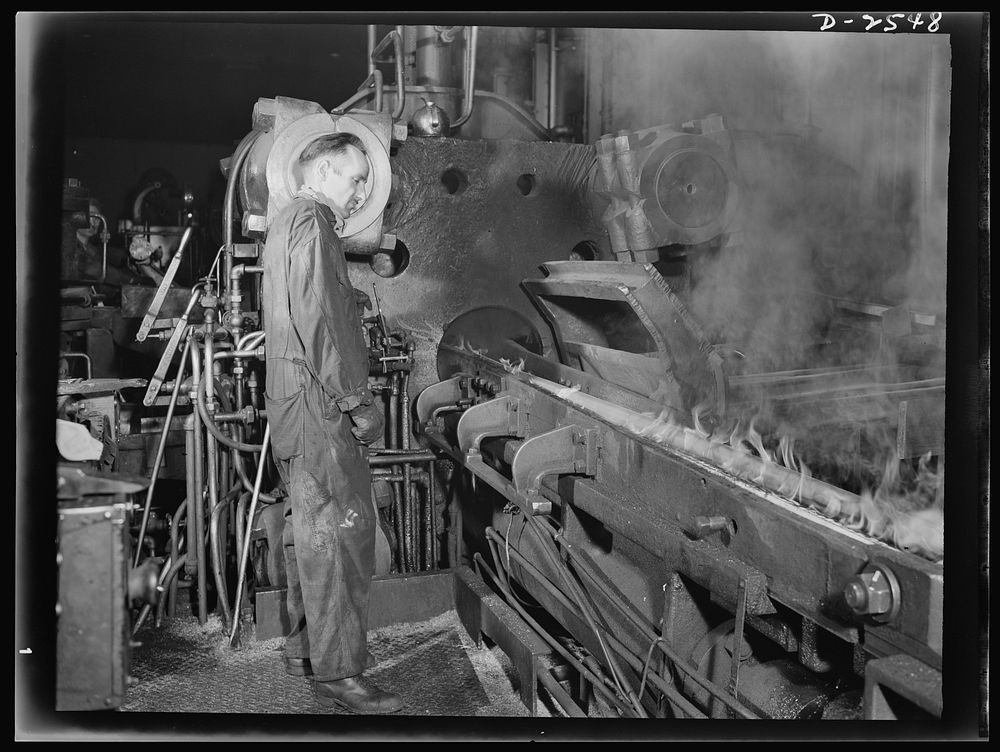

Conversion. Copper and brass processing. This picture shows brass rod coming from the extrusion machine. Red hot brass billets (solid cylindrical castings) are pushed by tremendous force through a steel die in the extrusion press to form rods of various shapes, or hollow shells that are subsequently made into tubing. The metal is ejected from the extrusion press like tooth paste from a tube. Chase Brass and Copper Company, Euclid, Ohio. Sourced from the Library of Congress.

Conversion. Copper and brass processing. This picture shows brass rod coming from the extrusion machine. Red hot brass billets (solid cylindrical castings) are pushed by tremendous force through a steel die in the extrusion press to form rods of various shapes, or hollow shells that are subsequently made into tubing. The metal is ejected from the extrusion press like tooth paste from a tube. Chase Brass and Copper Company, Euclid, Ohio. Sourced from the Library of Congress.

View public domain image source here

Public DomainFree CCO U.S. Government image for Personal and Business use